Stay connected If you would like details of our latest news, events and opportunities sent directly to your inbox, sign-up to receive the Sciontec e-newsletters.

Home to some of the most

sophisticated laboratories

for sensor & IoT technology

development in the UK.

The facilities housed in our laboratories enable entrepreneurs and businesses to produce robust prototypes and proof of concept devices. This allows them to demonstrate new developments with customers, partners and investors and, coupled with the invaluable business support that Sensor City offers, will speed up the process of bringing their products to market.

If your business has big IoT aspirations, but doesn’t know where to start, download our free 2020 Guide to IoT Adoption and take the first steps to unlocking sustainable growth.

Design, make, test

and validate

The laboratories and technical workshops on site can facilitate the design, creation, testing and validation of novel sensor and Internet of Things technology concepts. Sensor City provides rapid prototyping services and engineering support, carried out by a multi-disciplinary in-house team, as well as companies being able to access some of the equipment independently.

Design and scope

With over £1m of state of the art equipment in purpose-built laboratories, the core operational objectives of Sensor City are to:

- Provide rapid prototyping services, reducing time to market

- Provide engineering support and access to equipment that companies would not otherwise have access to

- Increase the skill levels of individual and companies

We can provide hands on support to help with any challenges and access to industry standard packages to allow CAD design of new products and testing using simulation software.

- Electronic, mechanical, optical and software design suites

- CAD/CAM software with finite element analysis and computational fluid dynamics

- Control and data logging software

- Virtual Reality suite (HTC VIVE Business edition)

Make

All Sensor City Laboratory equipment can be used for work commissioned through the Sensor City laboratory team, whilst some can be used directly on demonstration of competency and in accordance with our Laboratory Passport Scheme.

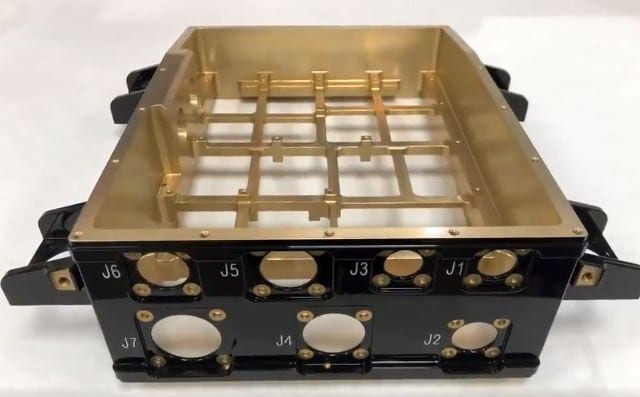

Sensor City has a state of the art electronic fabrication laboratory with technical support for the design and application of novel sensors. We are particularly proud of our LPKF Laser Direct Structure machine which allows PCB design and print onto 3D irregular surfaces and is a unique PCB manufacture resource in the UK.

Providing everything that start-ups need to complete the production of first prototypes, our mechanical laboratory is manned by highly trained technical and engineering support staff, to help get the best out of the equipment and develop appropriate housings for innovative products.

Key equipment includes:

- LPKF electronic prototyping suite – including LPKF LDS for PCB manufacture on irregular surfaces

- Surface mount pick and place

- CNC machining tools

- 3D printing (Ultimaker, Formlabs, Stratasys)

- Laser cutting

- Optics equipment – including high resolution digital microscope, high speed camera and infrared camera;

- Oscilloscopes, meters and signal generators;

- Electronic and environmental testing equipment;

- Virtual Reality suite (HTC VIVE Business edition);

- Soldering Stations and hand tools;

- Altium and SolidWorks

Test

Optical Laboratory

Our optics laboratory allows clients to develop and test optical sensors and provides access to:

- Optical bench

- Optomechanical holders and common optical components

- Spectrum analyser

- High speed camera

- Keyence microscope

- Calibration light sources

Validate

When the product is made and ready to go, Sensor City has all the equipment necessary to validate its performance and functionality, including precompliance RF and EMC validations to provide confidence that novel devices are fit for purpose. For larger products we can connect companies in resources within our partner Institutions.

- Environmental EMC testing

- Anechoic chamber access

Being able to utilise the specialist skills and lab resources at Sensor City has been a game-changer for us.

It’s enabled us to develop our technology and given us the impetus to expand our team.

Take a virtual tour inside Sensor City

Virtual tour